Uncategorized

A Comprehensive Guide about Custom Product Packaging

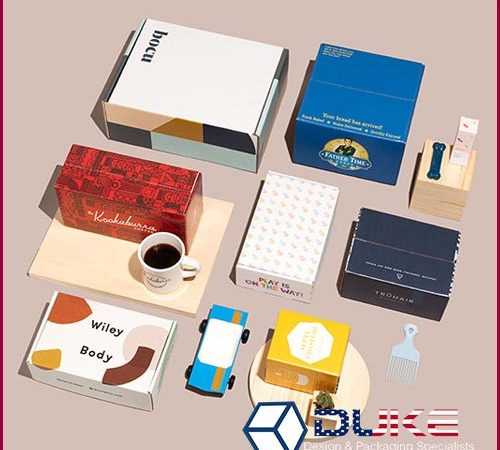

No one can deny the fact that every physical or digital product requires some packaging material for them. Many people like to go with blank or pre-made boxes while the majority of the audience likes to choose custom product packaging instead of blank. For that purpose, we are going to publish a complete, comprehensive, and detailed guide about custom packaging. We will cover all the information starting from basics to advanced. Now, without wasting any time let’s move on to the core parts of the topic. We will discuss the basic characteristics of boxes that are judged by its size, stock, style, and printing on it.

Sizes:

Before ordering the custom boxes, the first step is that you should know about the dimensions of the boxes that you want to order that are usually measured in terms of height, width, and depth. In custom packaging, you have the freedom to choose the snug or loose fitting boxes for your product as per your own desire. If you don’t know how to measure the sizes of the box, just measure the exact dimensions of your product and provide it to your custom packaging company. They will suggest an accurate size for you.

For that purpose, you can put a scale or ruler near your product. In this way, you can easily measure the dimensions of any good. Usually, most of the companies prefer the dimensions in inches. While you can also provide them in cm or mm as per your easiness.

Stock:

This is an important section that you should read thoroughly before ordering any kind of custom product box for your business. Most of the time cardboard, Kraft, the corrugated, and rigid stock is used for manufacturing the custom boxes. Now it’s an important question that, how to choose a stock for your boxes? We will answer that question in detail.

From the above-mentioned stock categories, rigid is somewhat different because that is thick and is used for the packaging of luxury products. They are also expensive as compared to the other options that why it is recommended for the packaging of luxury products only.

Now let’s talk about the shipping boxes. There are several kinds of boxes that are directly used for the purpose of shipping. For that purpose, we recommend the corrugated stock as that is perfect for the boxes that are going to be used for the direct shipping purpose. Usually, mailer boxes are used for that purpose with roll end tuck style. While large shipping cartons are also used to put small boxes in them.

For the normal retail products like cigarettes, candles, etc. cardboard or Kraft stock is a considerable option. For the products with normal weight thickness ranging from 12pt to 24pt is used. Cardboard and Kraft, both are known as eco-friendly stocks as well. Kraft stock is light brownish in color by default but cardboard stock is white in color. I hope that your misconceptions regarding the stocks would be clear now.

Box Style:

After choosing the box dimensions and stock, the next step is the selection of your box style. The most commonly used box styles are given as follows

- Straight Tuck End

- Reverse Tuck End

- Double Wall Tuck Front

- Auto-Lock Box

- Snap Lock Box

- Hanger Style

- Gable Style

- Cigarette box

- Foldable Style

There are many other styles as well but we have tried to mention some of them which are in high demand. Most of the time the above-mentioned styles are demanded by the customers.

Printing:

The last part is about printing on custom boxes that make them unique and attractive. Most of the companies are using digital and screen printing on custom packaging boxes. While some of the top-notch companies are offering offset printing technology now. Offset printing technology is the best option that has clean results and also has a huge variety of applications.

Offset printing is different from digital and screen printing. In offset printing, the image or link is first transferred on a rubber blanket. In the second phase, it is transferred on a printable object. If your quantities are higher e.g. above 1100 then you should surely go with the option of offset printing.

It can be done on all categories of the stock. Moreover, you can use Pantone or metallic ink with this process that can make your boxes attractive. Also, some add on like foils, lamination, PVC windows, etc. can make your packaging box much more attractive as compared to the normal box. That’s why it can attract more customers to your product. We always prefer offset printing due to several reasons.

The final Conclusion by Dukepackaging.com

So, we have shared completed details about custom product packaging that you should know before the shopping of custom boxes for your products. This guide also covers the matter from basic to the advanced level. I hope it will help you a lot in selecting the right custom boxes for your needs.[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]